What’s Fixable?

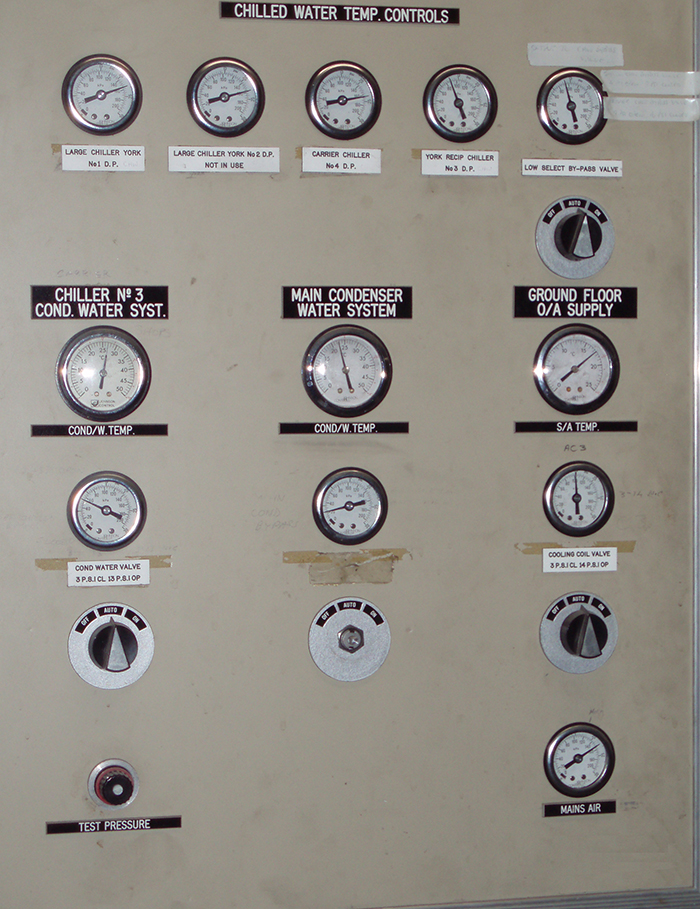

The Pneumatic valve in our picture here works but has two main issues, both of which are fixable.

First, the valve stem is leaking.

There are several methods to resolve this and avoid the expense of replacing the valve. If you do chose to replace the valve you are not going to find a valve that is directly compatible. You are going to need to do a few modifications to get right, hopefully, not major.

Second, the actuator is either leaking or not calibrated to the air pressure value for the controlled action.

There is a “diaphragm” inside. these perish over time and can often be replaced. Problem solved. (there’s a bit more to it but not much)

Air Compressor

HVAC Pneumatic Controls need an air compressor to work. This air compressor would typically include a small three-phase electrically motor which would stop/start 24 hours a day.

Maintaining air line pressures of around 24 to 32 PSI so the systems would function.

The vessel would collect water as apart of the air compressing process. This water, subject to the proper maintenance of the system, would end up in the pneumatic lines and even the pneumatic controls components.

This can be fixed. With a few additional specialized components and a little patience, we can achieve some accuracy and regain control

E to P | P to E Transducers

Electronic to pneumatic transducers and Pneumatic to Electronic transducers

These transducers can save you thousands and keep your system going. Not as good as full digital electronic, but, why upgrade if you don’t have to.

There will always be accuracy issues, but these can be minimized enough to gain control without spending millions of dollars.

Calibration is the key (and clean airlines – no water) and you will gain enough control with enough accuracy to carry on for some time.

Pneumatic Damper Acutators

These devices typically have heapes of torque and were one of the main selling factors in their day, this is because you need fewer actuators for the same set of damper modules than you would compared to an electronic configeration.

The Electronic to pneumatic transducers work well here. you need to be super accurate and you can control your economy dampers well enough to optimize the outside air as you should.

keeping these in service will save you the cost of new damper modules and the wiring and the electronic controller(s)

Pneumatic Controls

Messy! This one is not too bad. Some commercial building will have separate panels and keep it tidy, others will just have their pneumatic controls bolted to the wall and hope fo the best. usually on a wooden back board.

To be frank, it is not a huge issue, unless you are switching 240 volts and have exposed terminals. That will need to be made safe and properly covered. (We are electricians and can do this for you)

There are many way to fix this and improve serviceability. add some filters, and a few other stabilizing components to enjoy longer periods with fewer break downs.

Maintenance

HVAC Pneumatic Controls need maintenance. and we would recommend at least quarterly if not monthly.

Don’t leave it to chance or “run to fail” because it will be costly to recover and may have been easily averted.

Simlar with your air filters in your air handling units and fan coil units. Change them regularly, every six months. it is worth every penny. It will save you money at the other end on the electrical bills.

Talk to about a package deal or a single discipline service. we leave it up to you. there is opportunity and risk whatever you decide, so please call to discuss so at least you can make an informed decision.