Air Conditioning Services

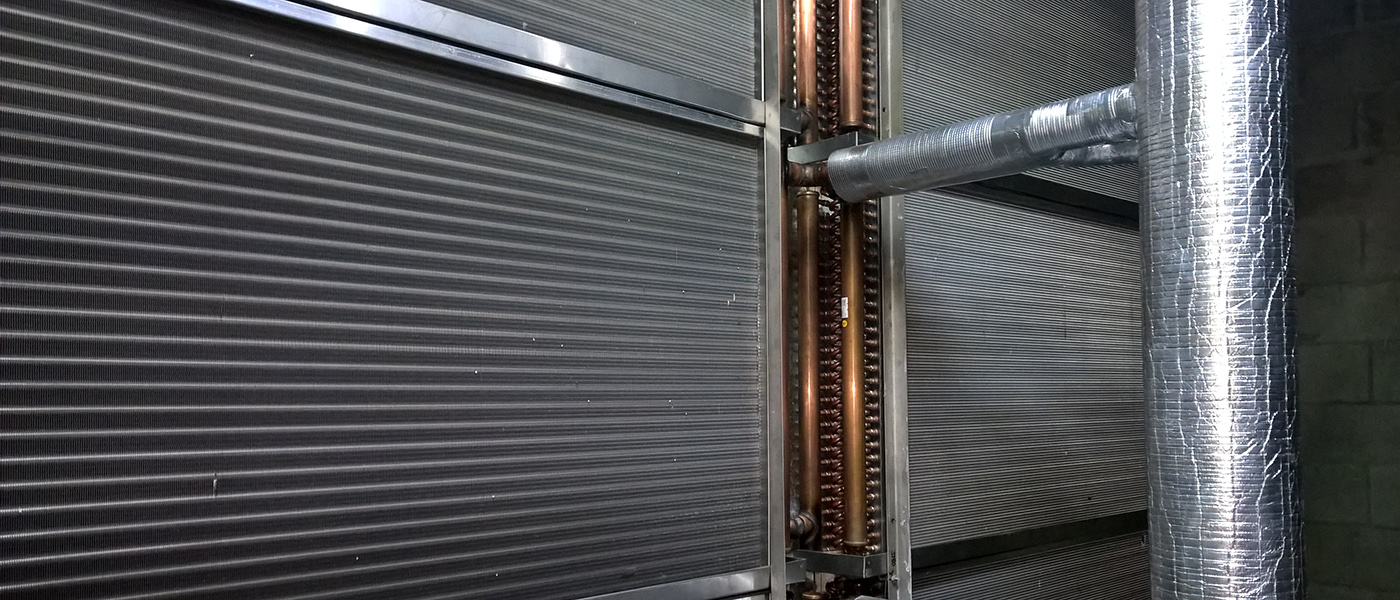

Cooling Towers

Chemical Dosing For Cooling Towers

Remote Monitoring, with alarm parameters, can be implemented into the cooling tower water treatment and condenser water system.

Consider the following applications which we have implemented for clients in the past:

- Alarms from the actual Chemical dosing System can be mimicked via salve relay into the Building Management System

- Monitor points via floats and switches can verify the water levels in the tower

- Water differential pressure switches can monitor if the condenser water pumps is activated and if there is water flow

- Water static pressure sensors can monitor the water pressure in the pipe

- The water meter serving the “top-up” pipe can be monitored, and the amount of water being used by the tower can be logged.

- These points and others can be alarmed against a given and adjustable set point.

The typical dosing equipment uses 4-20milliamp outputs for Biohazard and other measurements. These signals can be scaled and displayed on most Energy Management or Building Management Systems. “Volt Free Contacts” are often available to signal an alarm when readings are high/low or a chemical is out. Simple, straightforward strategies for remote monitoring of your dosing equipment.

Condenser Water Losses

Town Water “top up” Metering.

Water meter vendors often provide a pulse output to the Building Management System (BMS) or Energy Management System (EMS). Various brands provide differing levels of accuracy and price. Water meters can be provided for large pipes to serve cooling towers, town mains, and similar.

Condenser water temperatures Logged.

Logging the condenser water temperatures entering and leaving the cooling tower and an immediate picture of how effective the cooling tower becomes apparent. This is ideal for considerations towards energy efficiency and also fault monitoring if the fan motors have ceased operation.

Fluid Energy Meters

Fluid energy meters can be implemented at the tower or at the equipment or data room that uses condenser water for cooling purposes. An integer is given by the High-Level Interface (HLI) of the Fluid energy meter for logging. This integer is typically in Kilo joules which is calculated by the amount of water flow through the meter and the temperature entering and leaving the system, i.e. that amount of energy that has been transferred to the condenser water system to be taken away and expelled at the cooling tower.