Intelligent Building Automation

Implement an Intelligent Building Automation Platform and Improve data mining and NABERS Assessment Potential

Intelligent Building Automation | Are you seeking a solution that will increase the performance of building assets and reduce costs with a prompt return on investment?

Intelligent Building Automation | Team Experience

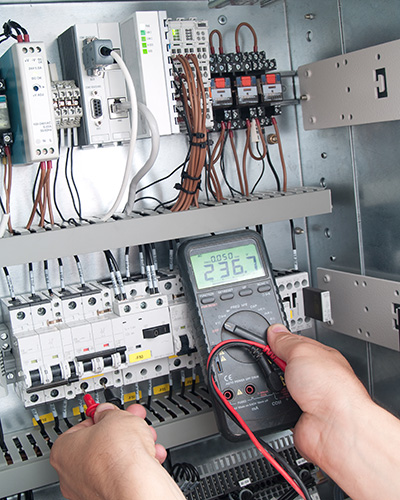

Our team has the experience and the knowledge to deliver a variety of systems, networks, open platforms and protocols to suit most situations.

New Installations, Refurbishments, Upgrades, Extending Existing Systems

We can supply, install, commission, Engineer, program, service, repair, and design as required.

Integration into existing buildings providing refurbishment, upgrades and new systems to meet a specification or given task.

We are not aligned with any particular brand or protocol; hence we are offering the “best of breed” technology options from a variety of system vendors, both locally and overseas

Automation strategies.

Automation Strategies and Engineering Design are selected to improve the operations and sustainability of the building in consultation with our client’s Consultant or Engineer.

Our services are designed to maximize reporting efficiency for Sustainability and Facility Maintenance Management. This data resource is invaluable for streamlining Audits and Assessments as well as the Day-to-day Operations of the Building. It is the foundation of the B.I.M strategy.

Commercial Building Automation:

Building Automation Systems (BAS) have varying degrees of idiosyncrasies, branding, and characteristics, but they all have common programming and hardware features that can be found across different brands. The advantage for our clientele is a hardware device for their system can often be sourced from alternate vendors, it will just have a different label.It will still work in their system, although the vendor is different.

Some of these common programming features are in built, at a microchip level, into the devices. The chips typically come from the same factory and are sold to different equipment vendors. They often have the same inbuilt features, especially with energy management strategies. These inbuilt strategies are rarely activated (optimization, for example) and are waiting to be switched on.

Depth of Building Integration

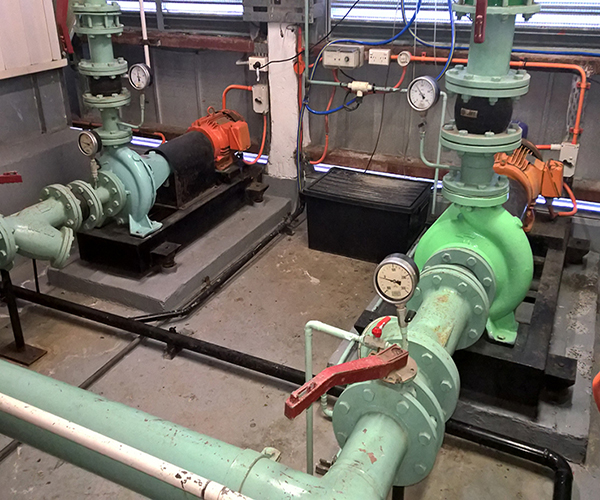

Any Intelligent Building Automation system will only ever be as good as it’s “depth of Integration” into the facility.

The system may have all the features and capabilities of recent “state of the art” technology, but if the system is superficial by engineering design, it will only provide superficial results.

The more you connect and integrate technology into the various systems of the building, the more information you can gather, and the more visibility the Engineer has.

When the Engineer can see more, then the decisions to make changes are based upon evidence instead of a “idealist” thinking.

Engineering Building Automation

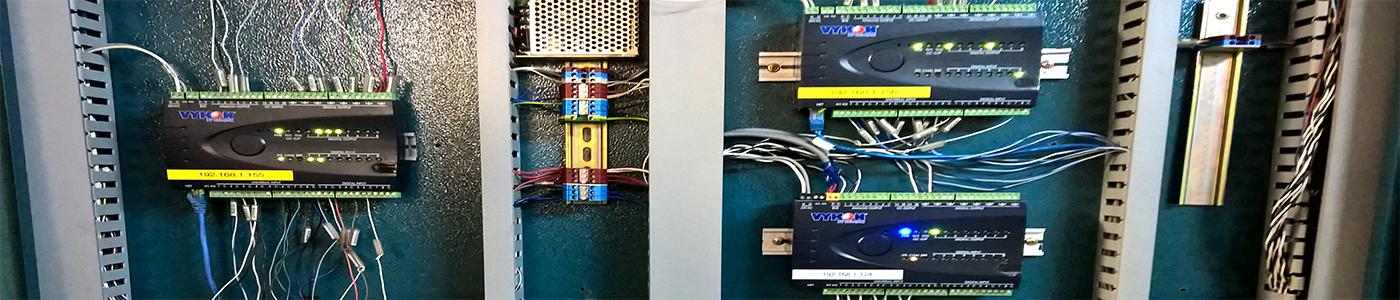

We can often improve an existing Building Automation system to offer improved returns for the commercial Landlord clientele.

Consideration is given to the engineering of an Automation system for sustainability strategies, data collection, reporting, other system interfacings, Maintenance Management, internet functionality, and overall Facility Management practices in the objectives of the landlord.

Our goal is to optimize what is currently available, with the most current technology, at minimum cost to offer the greatest value to our clients.

We consider strategies such as:

- 1. to drive the technology to maximise reporting, thereby making NABERS and ongoing Auditing easier

- 2. to maximise monitoring to achieve high visibility into the operation of the facility

- 3. to maximise the return on investment of capital spent on major plant equipment

- 4. to be scalable to enrich energy conservation strategies

- 5. to be expandable to monitor waster, water & energy Meters

- 6. to function creating and recording data for historical analysis

- 7. to export data to third-party software for further use

- 8. to be active in the “now” internet applications

- this list is not exhaustible, its up to you!